19 MW CONTROL PANEL FOR HEATER REGULATION

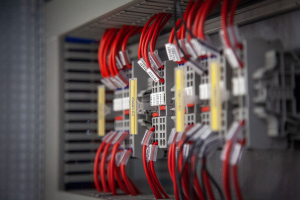

Delivered a control panel for a fluid heather project. The system is composed of four units for managing a total power of 19 MW. There is a central CPU connected through the network to the relative peripherical modules.

The control panel is connected, through the Profinet protocol, to the customer DCS system, which centrally manages all the plant processes.

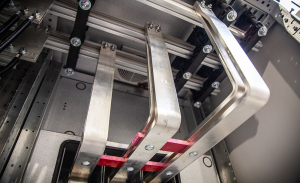

The fluid temperature is controlled by a hybrid system that works in steps, by combining the continuous adjustment of SCR with the on/off one of the contactors. In this way, the ratio cost-performance is optimised.